Drynamics LLC is a Wisconsin based entity, which assists clients in enhancing spray-drying systems for the food and dairy Industry. Established in late 1999, Drynamics LLC has provided  customers with services including project management, relocation and reinstallation of equipment, and design/fabrication/installation of specialty components such as high efficiency dual cyclones for large spray dryers, and fluid beds. Powder preparatory systems designed for clients include CIP cleanable dehumidification units to maintain the critical cooling and the sanitation level required for the pneumatic conveying of specialty powders and ingredients. In the past several years, many upgrades and modifications have been conceived by Drynamics LLC and applied to existing drying systems. These include enhancements to Filtermat multi-stage dryers and the conventional co-current tower dryer designs.

customers with services including project management, relocation and reinstallation of equipment, and design/fabrication/installation of specialty components such as high efficiency dual cyclones for large spray dryers, and fluid beds. Powder preparatory systems designed for clients include CIP cleanable dehumidification units to maintain the critical cooling and the sanitation level required for the pneumatic conveying of specialty powders and ingredients. In the past several years, many upgrades and modifications have been conceived by Drynamics LLC and applied to existing drying systems. These include enhancements to Filtermat multi-stage dryers and the conventional co-current tower dryer designs.

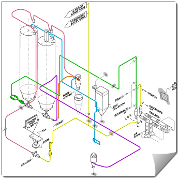

Air system modifications provided by Drynamics LLC have promoted better airflow and temperature equilibrium therefore promoting better evaporation and drying characteristics. Other ways to optimize a dryer system are to reduce the CIP turn around cycle which is accomplished by proper application of cleaning devices and the minimization of multiple circuits by utilizing higher capacity pumps. In today’s world of high production requirements with minimal downtime these are just a few of the techniques which can boost your company’s profits and efficiency.

characteristics. Other ways to optimize a dryer system are to reduce the CIP turn around cycle which is accomplished by proper application of cleaning devices and the minimization of multiple circuits by utilizing higher capacity pumps. In today’s world of high production requirements with minimal downtime these are just a few of the techniques which can boost your company’s profits and efficiency.

Drynamics LLC will streamline your drying system and fortify your bottom line!

Drynamics LLC -- The “dynamics” of spray drying established Sept. 1999.

- Paul Costello - Owner/President has held the following positions:

- Director of Engineering at a stainless steel fabricator in Fond du Lac, Wisconsin (1998 - 1999).

- Project Manager at an Italian Cheese Manufacturer for corporate and plant equipment projects (1990 - 1998).

- Filtermat and Tower Dryer designer at the original Damrow Company. Designed, detailed, and provided purchase specifications for dryers worldwide (1977 - 1990).

Our Services include:

- Increased air flow through process

- Increased production profiles

- CIP upgrades to minimize downtime

- Process design modifications

- Particulate collection upgrades

- Induction of high efficiency collection systems

- Conveying systems

- Packaging systems

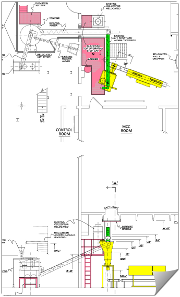

- Complete design and CAD drawing service

- On site Project Management during installation

Spare Parts Inventory

In addition to the design upgrades and technical consulting available, spare parts for the original Damrow dryers are also available. These include silicone manhole gaskets, sight-glass gaskets, cylindrical sight tubes for under cyclones, and CIP devices (both OEM and special USDA approved versions).